Filament yeTPU inochinjika 95A 1.75mm yekudhinda kwe3D Zvinhu zvakapfava

Torwell FLEX TPU ine kuomarara kweShore kwe95 A, uye ine kureba kukuru pakuputsika kwe800%. Batsirwa nekushandiswa kwakasiyana-siyana kweTorwell FLEX TPU. Semuenzaniso, mibato yekudhinda ye3D yemabhasikoro, mashock absorbers, marubha ekuvhara uye ma insoles eshangu.

Zvimiro zveChigadzirwa

| Brandi | Torwell |

| Zvinhu | Polyurethane yemhando yepamusoro yeThermoplastic |

| Dhayamita | 1.75mm/2.85mm/3.0mm |

| Huremu hwese | 1 Kg/chipunu; 250g/chipunu; 500g/chipunu; 3kg/chipunu; 5kg/chipunu; 10kg/chipunu |

| Huremu hwese | 1.2Kg/spool |

| Kushivirira | ± 0.05mm |

| Lsimba | 1.75mm(1kg) = 330m |

| Nzvimbo Yekuchengetera Zvinhu | Yakaoma uye ine mhepo inofefetera |

| DKugadzika kwemimhanzi | 65˚C kwemaawa masere |

| Zvinhu zvekutsigira | Isa chikumbiro neTOrwell HIPS, Torwell PVA |

| CKubvumidzwa kwekusimbisa | CE, MSDS, Reach, FDA, TUV uye SGS |

| Inoenderana ne | Reprap,Ultimaker, End3, Creality3D, Raise3D, Prusa i3, Zortrax, XYZ Printing, Omni3D, Snapmaker, BIQU3D, BCN3D, Bambu Lab X1, AnkerMaker nedzimwe printers dzeFDM 3D |

| Pasuru | 1kg/spool; 8spools/ctn kana 10spools/ctn bhegi repurasitiki rakavharwa rine mushonga wekubvisa tsvina |

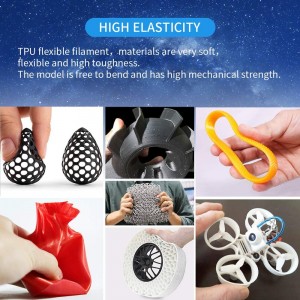

Filament yeTorwell TPU inoratidzwa nekusimba kwayo kukuru uye kuchinjika, senge purasitiki nerabha zvakasanganiswa.

95A TPU inodzivirira kukwenywa zvakanyanya uye ine kudzvanywa kwakaderera zvichienzaniswa nezvikamu zverabha, kunyanya kana paine zvinhu zvakawanda zvinozadzwa nerabha.

Kana tichienzanisa netambo dzakawanda dzakadai sePLA neABS, TPU inofanira kufambiswa zvishoma nezvishoma.

Mamwe Mavara

Ruvara rwuripo:

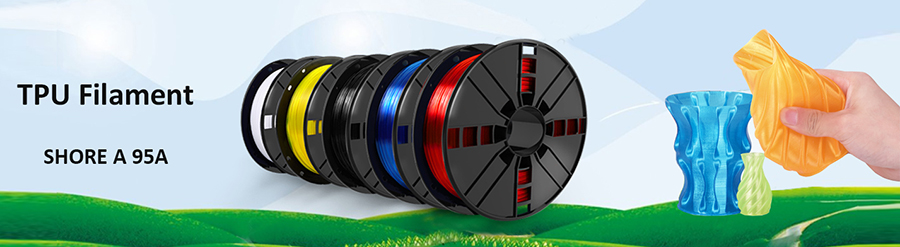

| Ruvara rwekutanga | Chena, Dema, Tsvuku, Bhuruu, Yero, Girini, Gireyi, Orenji, Rinoonekera |

| Gamuchira Mutengi PMS Ruvara | |

Kuratidzwa kweModhero

Torwell TPU Flexible filament inofanira kudhindwa nekumhanya kwakaderera pane zvakajairwa. Uye kudhinda nozzle type Direct Drive (motor yakabatana ne nozzle) nekuda kwemitsara yayo yakapfava. Torwell TPU Flexible filament applications dzinosanganisira zvisimbiso, maplugs, magaskets, machira, shangu, key ring case yemota-hands-bike parts shock and wear rabber seal (Wearable Device/Protective applications).

Pasuru

TPU ine 1kg roll ye3D filament ine desiccant mu vacuum package.

Spool yega yega mubhokisi rega rega (bhokisi reTorwell, bhokisi reNeutral, kana bhokisi rakagadzirirwa rinowanikwa).

Mabhokisi masere pabhokisi rimwe nerimwe (saizi yebhokisi 44x44x19cm).

Iva nechokwadi chekuti TPU filament yako yakachengetwa munzvimbo yakaoma

Ndapota cherechedzai kuti TPU ine hygroscopic, zvinoreva kuti inowanzo tora mvura. Saka, ichengetei isina mhepo uye yakachengetedzwa kubva muhunyoro mumudziyo wakavharwa kana mubhegi rine dehumidifier. Kana TPU filament yako ikanyorova, unogona kuiomesa kweinenge awa imwe chete pa70°C muovheni yako yekubikira. Mushure meizvozvo, filament yacho inenge yaoma uye inogona kugadziriswa seyakatsva.

Zvitupa:

ROHS; REACH; SGS; MSDS; TUV

Mamwe Mashoko

Torwell FLEX inogona kushandiswa zvakasiyana-siyana uye inogona kushandiswa mumhando dzakasiyana-siyana dzekudhinda kwe3D, zvichiita kuti ive sarudzo yakakwana kune chero munhu anoda tambo inochinjika inogona kusangana nezvaanoda chaizvo. Ungave uchidhinda mamodheru, maprototypes kana zvigadzirwa zvekupedzisira, unogona kuvimba neTorwell FLEX kuti ikupe maprinti emhando yepamusoro anoenderana kana kupfuura zvaunotarisira.

Torwell FLEX ishinda itsva yekudhinda ye3D iyo ichachinja mafungiro ako nezveshinda dzinochinjika. Musanganiswa wayo wakasiyana wekugara kwenguva refu, kuchinjika uye nyore kushandisa unoita kuti ive yakakwana kune akasiyana mashandisirwo kubva kuzvigadzirwa zvekugadzira uye zvishandiso zvekurapa kusvika kune zvemafashoni. Saka wadii kumirira? Tanga neTorwell FLEX nhasi uye unakirwe nepfungwa dzakanakisa dzekudhinda kwe3D!

Kugara Kwakasimba

TorwellTPU flexible filament chinhu chakapfava uye chinonamira serabha, chakafanana neFlexible TPE asi kunyora kuri nyore uye kwakaoma kupfuura TPE. Inobvumira kufamba kakawanda kana kugogodza pasina kutsemuka.

Kuchinjika Kwakanyanya

Zvinhu zvinochinjika zvine hunhu hunonzi Shore hardness, izvo zvinosarudza kuchinjika kana kuoma kwechinhu. Torwell TPU ine Shore-A hardness ye95uye inogona kutambanudzwa kakapetwa katatu kupfuura kureba kwayo kwekutanga.

| Kuwanda kwevanhu | 1.21 g/cm3 |

| Nhamba Yekuyerera Inonyunguduka (g/10min) | 1.5()190℃/2.16kg) |

| Kuoma kwemahombekombe | 95A |

| Simba reKusimba | 32 MPa |

| Kureba paKuzorora | 800% |

| Simba reKuchinjika | / |

| Modulus yeFlexural | / |

| Simba reIZOD | / |

| Kugara kwenguva refu | 9/10 |

| Kudhindwa | 6/10 |

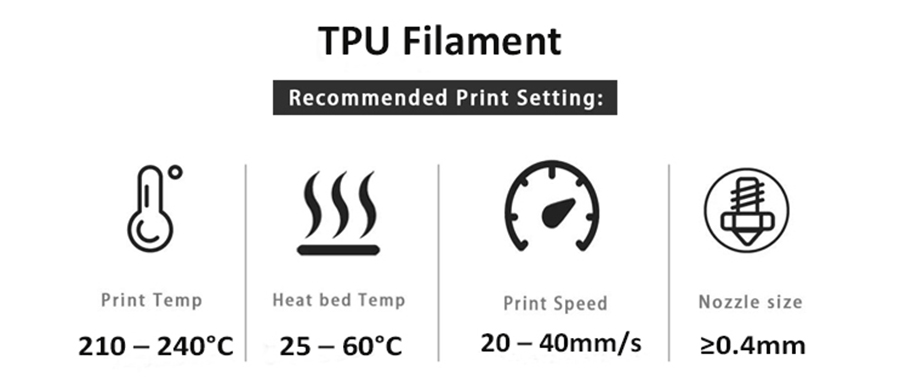

| Tembiricha yeExtruder (℃) | 210 – 240℃ Zvinokurudzirwa 235℃ |

| Tembiricha yemubhedha (℃) | 25 - 60°C |

| Saizi yemumuromo | ≥0.4mm |

| Kumhanya kweFan | Pa 100% |

| Kumhanya Kwekudhinda | 20 - 40mm/s |

| Mubhedha Unopisa | Sarudzo |

| Nzvimbo Dzinokurudzirwa dzekuvaka | Girazi rine guruu, bepa rekufukidza, tepi yebhuruu, BuilTak, PEI |

| Nzvimbo Dzinokurudzirwa dzekuvaka | Girazi rine guruu, bepa rekufukidza, tepi yebhuruu, BuilTak, PEI |

Zvinokurudzirwa kumaprinta ane direct drive extruder, 0.4~0.8mm Nozzles.

NeBowden extruder unogona kunyatsoteerera mazano aya:

- Dhinda zvishoma nezvishoma 20-40 mm/s Kumhanya kwekudhinda

- Kurongeka kwechikamu chekutanga. (Kureba 100% Upamhi 150% kumhanya 50% semuenzaniso)

- Kudzosera kumashure kwakadzimwa. Izvi zvingaderedza mhedzisiro yekudhinda isina kurongeka, ine tambo kana kuti inobuda.

- Wedzera Kuwanda (Sarudzo). Kuisa pa1.1 kunobatsira kuti filament ibatanidzwe zvakanaka. - Kubatidza feni mushure mechikamu chekutanga.

Kana uri kusangana nematambudziko ekudhinda neshinda dzakapfava, chekutanga, uye chinonyanya kukosha, deredza kudhinda, kumhanya pa20mm/s kunoshanda zvakanaka.

Zvakakosha kana uchiisa shinda muchina kuti utange kuburitsa shinda. Kana wangoona shinda ichibuda, rova muromo unomira. Chinhu chinoita kuti shinda ipfuure nekukurumidza kupfuura print yakajairika uye izvi zvinogona kukonzera kuti ibatwe mugiya rekubvisa shinda.

Isawo filament zvakananga kumuchina wekubvisa tsvina, kwete kuburikidza nechubhu yekudyisa. Izvi zvinoderedza kudhonzwa kwefilament izvo zvinogona kukonzera kuti giya ritsvedzere pafilament.